Whether it’s fair or not, the KNX systems integrator is always considered the middleperson when it comes to faults. Simon Buddle explains the value of harvesting error messages that might appear on the KNX bus, and outlines some strategies for turning them to your advantage.

How is everybody? Is it just about time to put away the sun cream and the sombreros? We managed to get our puppy swimming in the sea, and I spent a lot of time sitting in the kids’ paddling pool. It has, by any standards, been a pretty sweltering summer – some might even say too hot. And of course, when it is hot, you can bet your life on the control systems engineers’ phones being hot too.

I lost track of the number of calls; ‘The AC isn’t working,’ or ‘The AC is blowing stifling air,’ or ‘The AC keeps switching off’ etcetera, etcetera. Just like back in the day when I looked after AV systems, when the customer pressed a button on the touchscreen that you installed and Sky TV didn’t work – it was your fault, right? Did they ever ring Rupert Murdoch or the Sky installer who left the satellite box and ran for the hills as soon as they saw the 17-wire IRS system (Integrated Reception System) you’d installed? No, of course not. Your screen was the touchpoint for the action and therefore the first person on the call list.

From a client’s perspective, that’s not at all unreasonable. They have no understanding of the complexity of the software and wiring interconnects between that button push and the image appearing on their TV. Nor should they; that’s what we get paid for.

So, it is no surprise that when the sun comes out, we start to get calls in relation to AC issues, and this year was no different. At this point, I’d like to note that I’m absolutely happy to field those calls, as keeping in contact with clients is never a bad thing. However, it is also true to say that I am the middleperson in this instance, as I log-in to the KNX system, investigate what the potential issue might be, and establishing what it is. Once identified I’ll need to inform the client and the respective trade so that they can resolve the issue.

The value of error messages

In this case, it would seem obvious to cut out the middleperson and get the information directly to the AC company. However, when looking though the Mitsubishi AE200 AC system central controller touchscreen manual, there are pages and pages of error messages, with many pages having thirty or more errors per page. If you are responsible for looking after the air-conditioning, wouldn’t it be great to know what the fault was before you left the office?

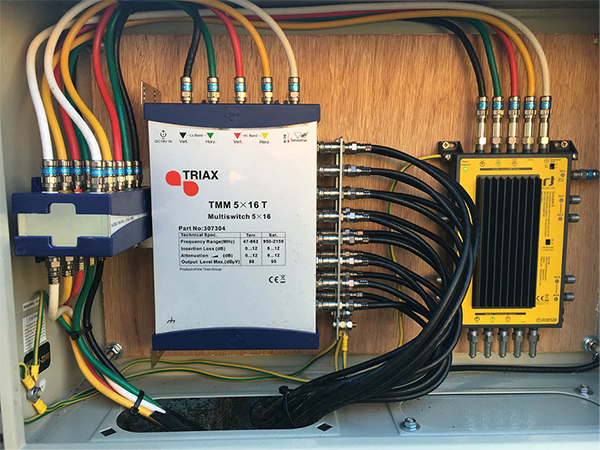

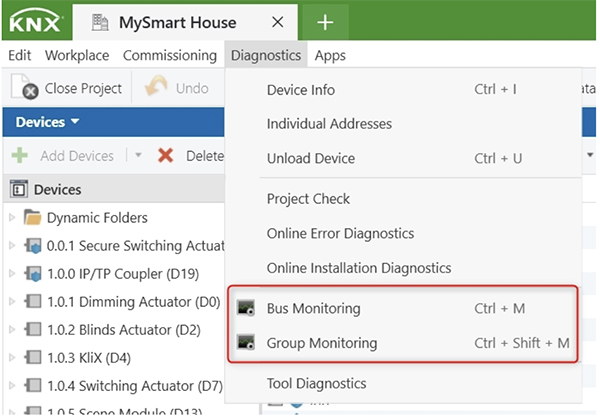

Well, with KNX, you are blessed with thousands of products, hundreds of manufacturers, and many different communication layers. And, importantly, anything that is transmitted on the KNX bus can be captured and retransmitted in real time. That is the secret of our success – we can bring in any error message that a device can transmit and send it on via email or SMS to the correct company or individual.

Of course, it is important to set the stage for this with the client at the beginning of the sales process, because whilst it is true that this is very much part of maintenance, it does require the correct product set to be installed in order to facilitate the procedure.

Alarms and errors

The most important item to work through and agree is ‘What is a fault?’ For example, it is common for data traffic to be interrupted or corrupted. This doesn’t stop the system working but might generate an error code that would subsequently clear down. The list of faults could be endless and many of them may not be relevant. From this list, we then need to decide what is a high-level alarm and what is low- priority. High-level alarms typically require immediate attention, whereas low-level alarms might be added to the next routine maintenance visit.

Once we have our lists, we can set about reporting them. If the alarm is, for example, dirty filters, then this error will go from a 0 value to 1 and stay that way until the filters are cleaned and the alarm reset. However, if we are monitoring a temperature value where the alarm may be set to trigger when a threshold is exceeded then we need to think about the frequency of messages to be sent. I got this wrong once when I set an alarm to trigger a message every ten seconds. Six emails a minute, or 360 emails per hour, or 4320 emails overnight – my inbox took a lot of clearing down in the morning!

Responsibility and timeframes

The last items to be agreed are who is responsible for each alarm and what time frame are they offering to provide a response. Once all these elements have been agreed, it must be documented, and copies given to all parties.

Conclusion

KNX can easily provide the technical solution to facilitate alarm messaging. Add a KNX email server onto the bus, agree the alarms and responsibilities, put it all down on paper and we have provided huge additional value for the customer. The value for us is the ongoing customer relationship and the maintenance contract, but more than that, is the peace of mind that the system is communicating directly with other businesses for the benefit of the end-users. Even though we may not consider ourselves the middleperson, we always are, and automating the process can deliver more accurate fault diagnosis and faster response times.

Simon Buddle CEng MIET, is a consultant for Future Ready Homes, a specialist in BMS and ELV services system design.