By Danny Lawless, ARK M&E Ltd.

By Danny Lawless, ARK M&E Ltd.

As KNX is being increasingly specified in home automation systems by consultants, especially in large multi-dwelling unit (MDU) high-rise buildings, the KNX part of the whole M&E (mechanical & electrical) tender is required to be costed as a specialist package.

Some project tenders can be multi-stage, with the early stages having a certain amount of flexibility in terms of budget for some specialist packages. KNX can sometimes be considered as one of these packages. However, later stages of the tender – if you’re lucky enough to be involved – require fixed costs for all packages, and this would include the KNX part. In this case, fixed costs must be submitted with detailed cost breakdowns in order to match the scope of the project. This isn’t an issue – it is no different to costing any other project, but how would these costs stand up say, 12 or 24 months later? Would they still be correct? How can it be assured that what is priced for will still hold up when the time comes to procure for the project? This is where some assistance from wholesalers is needed.

Changing costs

Large projects can be tendered over a long period. The entire process may take many months, with final awarding and appointment of the project possibly coming even further into the future. In some instances, this entire process can take one or two years before a project is even awarded, let alone be in the position to procure, install and commission KNX. This leaves the systems integrator with the worry of cost. What if prices rise? What would this mean for your tendered price?

Projects are tendered on a competitive basis, with open-book costs submitted to clients. Profit margins are contractually agreed at fixed percentages, typically anywhere from 5-15%. A 2-5% inflation rise could seriously hit your profit margin, if not overtake it, putting you into the red before you even begin!

This is a major issue, and one I have had to deal with. I suffered this recently on a project thanks to the annual 2-3% inflation rise and the further blow of the Brexit factor which caused a 10% rise in costs due to the fall in Sterling.

Imagine this on a large project! Such a rise could make it unviable in terms of profit. I was hit with this issue, and had to come up with a solution, and this is where the wholesaler’s help was needed.

Relationships between buyers and suppliers

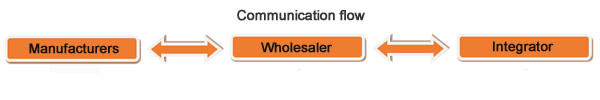

The prices come from the manufacturer, with the wholesaler as the intermediary. The manufacturers however, are not necessarily aware after one or two years, that a project they submitted prices for is still active, let alone about to start. After all, how many other projects have they priced since then? This is where the wholesaler needs to use its relationship with the manufacturer in order to negotiate that the original costs be honoured. Indeed this is what had to be done on my project.

In this instance, Bemco, a wholesaler with a long track record and experience in large M&E projects, was key in explaining to its suppliers that the project was still active and ready to procure, and that we needed to work with the original prices provided. Without this help and support from the wholesaler and manufacturers, the project would not have been a success. In my experience, manufacturers will always give contractors support, but after possibly two years, they may not remember the price they gave, which is where wholesalers’ help is needed to keep manufacturers updated on project activity.

Conclusion

Large projects differ from smaller, bespoke direct-client ones. To ensure that KNX is competitive and workable in larger projects, the pricing process has to be adapted. A clear understanding is required by all parties, right from the start. Of course, not all projects will be awarded, and some may not even stay as KNX, but to ensure the continued growth of KNX worldwide, we need every advantage we can get. For larger projects especially, costs have to be fixed for a longer period than the standard 28 days, thus ensuring that KNX is competitive when up against other automation systems.

Since this project, I have tendered and won other similarly large projects, with fixed costs agreed with the manufacturers and the wholesaler prior to tender. All parties were aware of the project and the nature of the tendering period, and the help of the wholesaler and manufacturers ensured that a commercially-secure process was in place. At the end of the day, we all want to see KNX becoming more prominent in larger developments. The more KNX projects there are, the better it is for us all.

Danny Lawless is an Electrical Engineer and KNX Integrator for ARK M&E Ltd, part of the JRL Group.

www.arkme.co.uk