By Sophie Thomas, Ivory Egg.

By Sophie Thomas, Ivory Egg.

We have been trying to control our built environment since at least 270BCE, when the first automatic control system device, a water clock, was invented. The first HVAC-related system came about in the 1700s through Rene-Antoine Ferchault de Reaumur’s scale thermometer and his ideas on temperature control of incubators based on an invention by Cornelius Drebbel. The 1920s saw the beginnings of building management systems (BMS) as we would recognise them today, with the birth of boiler control systems.

Since then, the use of BMS systems has become commonplace, especially in the commercial and public sectors. Buildings are becoming ever more complex, and with economic pressures, more scrutiny of energy consumption and shared and multi-purpose usage of buildings requiring scalability and flexibility, is it any wonder that BMS systems are being relied upon more and more?

What does BMS mean in practice?

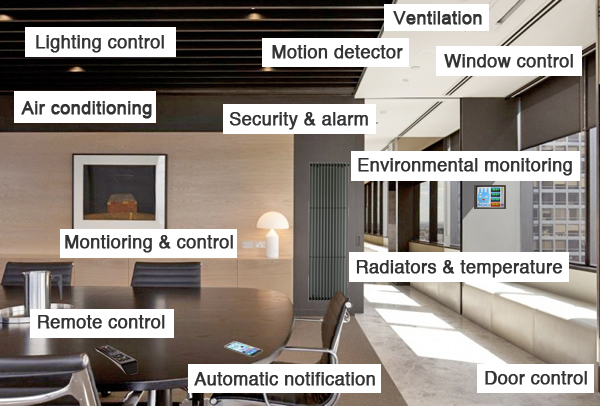

BMS generally refers to localised or centralised control of HVAC plant, but really it should also include lighting, shading and security control. Plant control requires numerous control points for valves, pumps, variable temperature valves, temperature sensors and fault inputs and a process to handle all of the control algorithms.

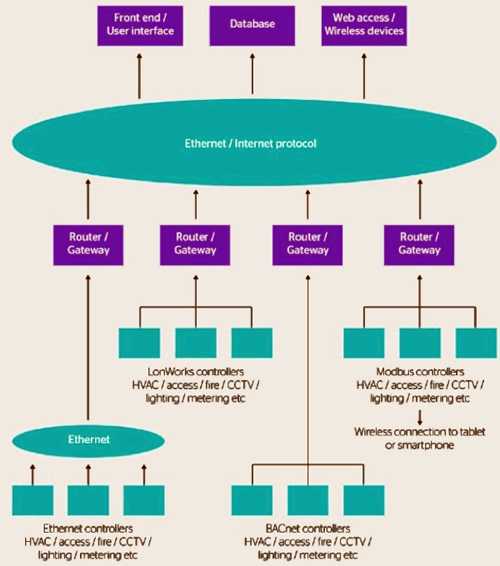

In a large building or network of buildings, you can see how the number of control points and devices and the related logic can become extremely complex. Modern buildings often rely on a number of different, sometimes proprietary systems or protocols such as BACnet, LonWorks, C-Bus, Trend or Modbus, to operate the different plant areas, and often use separate software packages, making it difficult to analyse and streamline data and get a harmonised, overview of the building’s performance.

Trying to combine data from numerous disparate systems is not only time-consuming but it adds to an already complex set up, and can lead to grey areas, data gaps and overlaps and, at worse, systems can conflict with each other. The outcome is an environment that is less than comfortable for the inhabitants, and harder to control for those responsible for maintenance.

Where does KNX come in?

KNX is of course a BMS system. It is also a distributed system, and so is ideal for allowing all devices around a building to talk to each other. It could certainly control the entire plant setup, but where a complicated plant room exists, KNX might not be best suited as a standalone solution. The reasons for this are three-fold:

• Plant products such as boilers and burners do not often have native KNX interfaces.

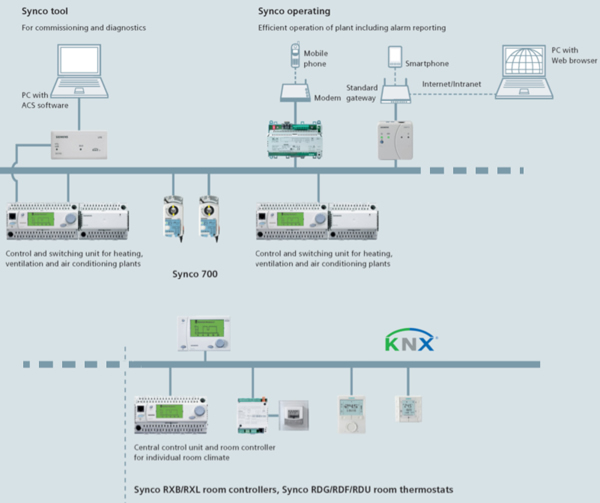

• With the exception of the Siemens Synco range for smaller-scale projects, there are no KNX plant controllers that can take control of complicated plant easily.

• The plant management and building infrastructure are often taken care of by different contracts, and are by nature cross-discipline, meaning it is very unusual for just one person or department to look after the building and plant management.

Not all BMS systems are always able to talk to KNX, and so combining KNX with another BMS could be seen as contentious, but there are products such as the Siemens Synco range that address this issue and allow for the best of both worlds through open data exchange.

KNX is the protocol of choice for building automation and control as it can be used cross-discipline, and it is scalable. In fact all but the most complicated buildings and plant rooms could be entirely run and managed with KNX devices. The number of KNX manufacturers is already large and is growing all the time, so there are KNX devices for all kinds of HVAC applications.

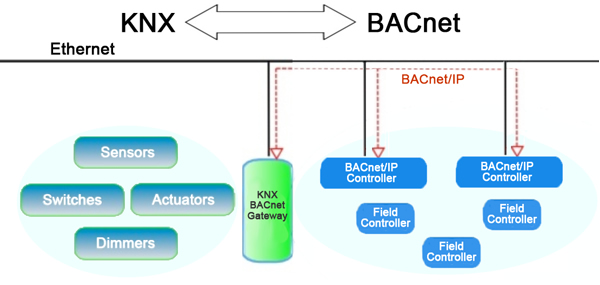

Due to the obvious advantages of KNX, it is very common to see a proprietary BMS being used for the plant control with an interface to KNX via a BACnet or Modbus gateway, allowing the extra functionality and the benefit of remote access and alarm notifications using one user interface. KNX integration is made simple when using BMS systems such as Tridium, as they offer direct KNX integration.

In cases where BMS systems such as Tridium or Trend are being used for complex plant control, KNX is the ideal choice for the field bus. The field bus is responsible for sensing and collating data from around the building and sending this information to the BMS plant controllers as well as taking data from the plant and relaying this information to users and maintenance staff through visualisation.

The use of one user interface is beneficial, as data can be analysed, graphed and interpreted so that reports can be made more readily available. With KNX, the option of remote access and the possibility of viewing the data on smart phones, tablets and laptops means that different managers, such as facility managers, electrical managers, IT managers, and security managers, can see the same data and have their input on the building’s operation.

Specifying and Installing a BMS

When choosing a BMS, it is important to consider the different areas that comprise a modern building and how the BMS can offer benefits to these and their inhabitants. Attention should be paid to the design, specification, installation and commissioning process in order to ensure a harmonized and effective BMS and avoid conflicts. With any BMS, maintenance will still be a factor, but with the use of KNX, this can be made simpler and less time-consuming.

According to CIBSE (Chartered Institution of Building Services Engineers) guidelines, any specified BMS must be capable of dealing with a future 20% increase in the number of points without compromising the system’s functionality or speed of operation. The scalability and ease of expansion within a KNX-based system make growth or even major alterations achievable and, very often, much simpler.

Can you use KNX combined with a BMS in residential environments?

Increasingly, we are seeing more complex plant requirements in modern residential projects, especially where technologies such as ground source heat pumps and solar water heating systems are used. As KNX is Europe’s most popular control platform, it makes sense to consider how we can combine the use of BMS systems and KNX in a residential environment. Basically, there are three options:

1. Use KNX for everything outside of the plant itself. All control of remote pumps, valves and all sensing is done within KNX which ensures that the system is cost effective. Room temperature regulation is all within KNX, so it is very easy to keep the cooling and heating systems from fighting each other. In addition, the heating solution is now an integral part of the other systems in the building, reducing complexity. This solution is ideal for applications ranging form the simple to all but the most complex.

2. Use KNX to provide the room regulation, with the BMS controlling the manifolds, pumps and valves directly. This allows for an integrated KNX keypad, easy integration with other building systems on the KNX bus, but still allows the use of a substantial plant BMS. The benefits however, are limited, as the potential of both the KNX and plant BMS solutions may be not be realised. In addition there could be substantial duplication in infrastructure.

3. KNX provides only the room temperature with all regulation and control performed in the plant BMS. If the systems integrator wants to steer clear of HVAC responsibility, they may prefer this solution. The KNX system however, will be massively under-used and the overall solution is likely to be significantly more expensive.

Conclusion

Proprietary BMS systems certainly have their place, but in order to make a system most efficient ecologically, physically and financially for inhabitants and managers, there is another option to consider.

KNX and BMS should not be seen as mutually exclusive. By understanding the complexities or indeed simplicities of the building, a decision can be reached as to what the best ratio of plant control and the use of KNX is. Both systems are powerful in their own right and their benefits should be harnessed through careful specification, planning and commissioning in order to create a system that will work at its peak now and in years to come.

Sophie Thomas is the Marketing and Events Manager at Ivory Egg (UK) Ltd, a supplier of leading KNX products and provider of KNX training courses.

You are welcome to comment on this article below.