By Mark Warburton, Ivory Egg.

By Mark Warburton, Ivory Egg.

Following on from last month’s article on ‘How to sell KNX‘, hopefully you have now won the job! So now we need to design a KNX solution.

KNX System Design

KNX provides flexibility, resilience and upgradability at its core, so it makes sense to approach system design with the same parameters in mind. Running a line per floor or distribution board provides the flexibility to create new line segments, quadrupling the number of devices supported. There is also redundancy built into the system, so if there were ever an issue with a power supply, it would only affect the floor it was on.

Always allow an overhead, be it on number of bus devices, number of fittings on a dimmer or rating of the bus power supply. This will ensure efficiency, upgradeability and reliability as the entire system will be working well within its design criteria.

Lighting

If the lighting design is being completed by a lighting designer, it is wise to allow for additional consultation, as there is still a lot of work to do. Establishing a clear framework for information is critical in order to ensure that all luminaires are dimmed correctly and power loadings have been considered. A recent article by George Lazos ’How to Solve it: The Lighting Table Tool for Successful Lighting Design’ explains such a framework.

Heating and Cooling

Seemingly complicated, but the basics are very simple indeed. Start by splitting up the room control, distribution and central heating plant.

Room Control

With most KNX thermostats offering two stages of heating and cooling, there are few room scenarios that cannot be controlled. This provides a lot of flexibility whether designed by a plumber or by a mechanical engineer.

Distribution

UFH manifold control can be very simple. To start with, obtain answers to the following questions:

• How many valves are required per zone?

• What is the voltage of the valves (230VAC or 24V)?

• Is local pump control required?

• What is the variable flow temperature required?

Most manifold controllers support both 24V or 230V valves, but it is important to check the loading: generally four valves can be supported with each zone, but this can vary. Many KNX manufacturers do not provide a switching relay on manifold controllers, so an extra relay unit will be required if there is a local pump.

For systems with radiators, a local valve controller on each is the simplest method, as these are powered directly from the KNX bus. Alternatively, they can be plumbed into a manifold, in which case, the approach is the same as UFH.

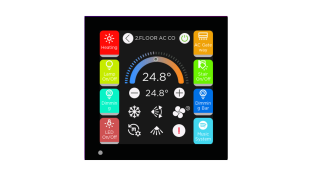

AC control comes in two main types: local or system wide, with both offering full two-way integration. It is key to get the details on the system being used – the relevant information is generally the model number of the internal unit.

Fan coil control is different, as this is normally based on a water medium not a refrigerant. Whilst a lot of fan coil units have proprietary controllers, the best option is to use a native KNX fan coil actuator, as gateways to proprietary controllers are rare, expensive and add complexity.

Central Plant Control

This may be as simple as control of the boiler and a few pumps, or it may require integration with a standalone plant control system. There are extensive articles about this elsewhere, so taking the time to understand the best solution, and drawing a clear demarcation between trades, can make all the difference.

Window Treatments

Often left to the last minute of the project, the benefits of exploring this aspect early are far- reaching. If motorised blind control is installed, it can be used to form part of the environmental control and provide large energy savings on heating and cooling. Essentially, in well-insulated buildings with enough glazing, the heat can be almost completely controlled with shading. A wide range of control scenarios are possible. However, to achieve the most benefit, full positional control of the blinds is required.

Conclusion

As KNX is able to control so many aspects of a building, it is always important to spend as much time getting your design right from the start. The very nature of KNX means that there are often simple solutions at hand – either for the above or for the numerous other devices or systems that can be controlled. By using products that have a higher level of functionality than required, allowing an overhead on system design and keeping good lines of communication open with other trades, you can ensure a smooth-running project.

Mark Warburton is the Technical Director of Ivory Egg (UK) Ltd, a supplier of leading KNX products and provider of KNX training courses. Mark is also a regular contributor to KNXtoday magazine.