Controlling lights is a major part of the world of KNX, and now that LED lighting is ubiquitous in homes, Simon Buddle discusses where the drivers should be placed and what types of driver to use.

Lighting is fundamental in all homes – we all have it and use it on a daily basis, but lights aren’t as simple as they used to be. For example, I have lights that I can switch via a conventional light switch, control via my phone, or simply talk to.

Invented by Tomas Edison in 1879, the incandescent lamp has had a surprisingly good run. It was a simple device; apply a voltage to a resistive wire and it glows, giving out light (and heat). Did you know that the typical incandescent lamp is 95% inefficient? That’s right, only 5% of the energy is emitted as light, the rest as heat. Can you imagine attracting investment in a new product these days with such a statistic? Anyway, it served a purpose for more than a hundred years without question. Now, however, we are squarely in the age of the LED.

The LED is more efficient, and comes in a multitude of shapes and sizes as well as any colour you can think of. Colour-changing LEDs bring moods and accent lighting that add drama and character to rooms and spaces. But with the LED comes a significant uplift in technical knowledge that is required to achieve a successful outcome for the client.

Drivers and locations

Conventional wisdom suggests that the driver for each light is located at the light fitting with mains voltage wiring running around in the ceiling to each driver. There are lots of reasons why this is the right approach, not least of which is that you know where the drivers are, and you can be fairly sure that each driver is capable of running a single lamp. But with smaller fittings, including LED tape, now becoming commonplace, is it time for a rethink on driver locations. Siting drivers away from the fitting has certain advantages and disadvantages.

Advantages

From a maintenance perspective (assuming a decent location is chosen), then ease of access for swapping out drivers is a big plus. Moreover, the opportunity to deal with heat dissipation better than in a ceiling void filled with insulation is another big positive. The physical wiring of the drivers is considerably easier for the electrician too. Another element not to be overlooked is the ability to specify larger drivers to run multiple lamps, which typically has financial and time-saving benefits.

Cable distance and size

A reasonably-sized space must be found and agreed upon to accommodate the drivers with easy access for maintenance, but this is not always straightforward when architects and clients are fighting over every inch. Ventilation also becomes more critical as you group multiple drivers together, but probably the biggest concern is the size of cable from the driver to the light fitting. As voltage goes down current goes up. As current goes up, so the need for larger cables comes into play. For example, with five metres of 12V LED tape at 14.4W/m, we are looking at current of 6 amps. That in turn means a 4mm cable between the driver and the LED tape, given a 5% voltage drop. So, the absolute maximum distance between driver and LED strip cannot exceed 9m. Of course, the problem is halved when you go up to 24V lamps, but we should always calculate for the worst scenario.

KNX drivers

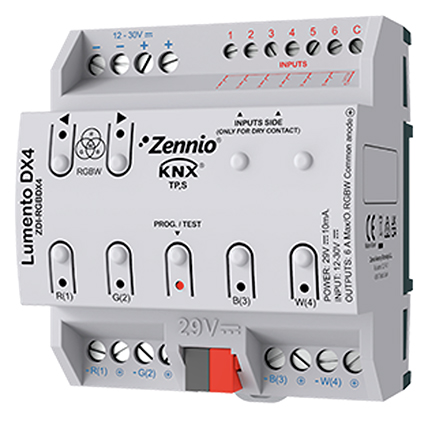

There is quite a bit to think about technically when you start to co-locate drivers. One more topic that is really worth discussing is the use of KNX drivers and actuators to replace those usually supplied with the lights. These are becoming increasingly prevalent on the market and really offer a great control solution, as well as an inexpensive route to lighting control.

You will need some form of lighting driver or transformer if you are not using 230V lamps, so why not buy a KNX-enabled driver and kill two birds with one stone? The cost of a good LED driver will be somewhere between GB£45 -90. Many of the KNX drivers are coming in at GB£80 – 120. Using a KNX-enabled driver represents a cost saving of around £100 per circuit, as there is no need to install an actuator at the headend.

Conclusion

LED continues to grow and is really the only game in town for most installations. With this comes a new way of thinking about drivers, locations, cabling, and costs. All of which add up to specialist knowledge that we are all well-placed to dispense, making us invaluable as part of the design and installation team. KNX continues to offer cost-effective solutions that, when used correctly, will improve energy efficiency for our customers and help our businesses to grow.

Simon Buddle CEng MIET, is a consultant for Future Ready Homes, a specialist in BMS and ELV services system design.