By Mark Warburton, Ivory Egg.

By Mark Warburton, Ivory Egg.

One of the fundamental benefits of the KNX system is the ease with which you can link devices together. A great example is a hallway with multiple keypads. Just put all button objects into one group address along with the circuits you want to control, and you’re done. No dealing with intermediate and two-way switches, not to mention the additional cabling you would need if you were using a standard electrical system. In this example the state of the keypad should always reflect the output i.e. if one keypad is on they all become on.

But what do you do when multiple inputs can have various states? How do you determine which state the output should be, given that there might be some inputs asking for it to be on and others asking for it be off? If you just combine all the inputs into one group address, then the last device to send a value will set the output, potentially overriding the message from the previous device which may still require the output to be on. For example, if you have multiple under-floor heating (UFH) manifolds in a project, they all need to be able to demand heat from the central heating system. If one sends an ‘on’ signal the system should remain on until ALL manifolds send an off signal. There are two different way of achieving this with either a logic gate or by using a more intelligent demand signal.

Logic gate

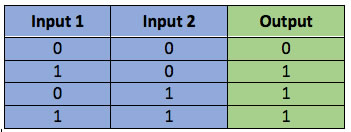

By connecting the different signals into an OR logic gate, we can be sure that the output will be in the correct state. OR gates work by storing the state of the input and turning on the output when Input 1 or input 2 is on. It will only turn off when both inputs are at 0. The following truth table confirms this. For more information on logic gates check out-

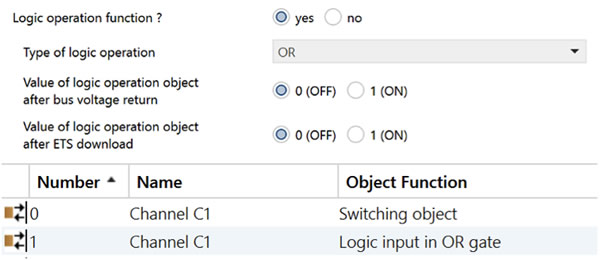

On most KNX actuators, it is possible to configure the output to have an additional logic function, but most are limited to two inputs; namely the switching object and an additional logic input.

This is perfect if you only have two demands to link together. But what if you need more? There are countless KNX devices, such as the Gira L1 or ABB ABA/S1.2.1. that offer additional logic functions along with dedicated logic devices.

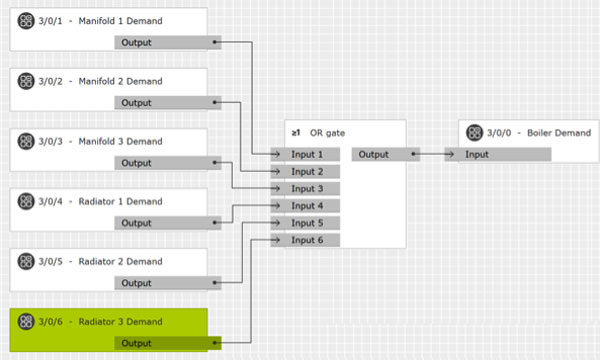

It is also common to use a central visualisation server, as these almost always have a graphical logic function. Regardless of which device you use, the process is the same. You will need to bring inputs into the logic block (or page) from each individual device using a group address each, then link the output of the logic to the output device – again, in its own group address.

In the image below, six different demands from manifolds and radiators are combined into a six-input OR gate. The output is then linked to the boiler, safe in the knowledge that it will be on when any of the inputs are demanding heat.

Is there an easier way?

Theben is one manufacturer that offers a much simpler way to link multiple manifolds or radiators together. You may still need to use logic blocks for other functions, but as heating is the most common place they are used, it’s a good start.

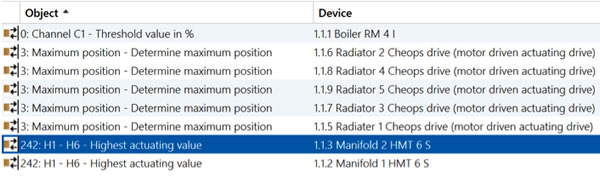

On the Theben Cheops Drive, Cheops Control and HMT 6 KNX or HMT 12 S KNX manifold controllers, there is an object called ‘Maximum position’ or ‘Highest actuating value’. In the case of the Cheops devices, this will have the position of the valve as a percentage, whereas the manifold controller will report the highest proportional demand value across all its inputs.

What makes these objects different from a standard feedback object is, when they are combined in a group address, they will check a received value and then send their own value if it is higher. This means that the last value will always be the highest demand, regardless of how many radiators or manifolds are linked together. This percentage demand could be linked to an intelligent central heating system that is able to modulate its output, which creates a very efficient system.

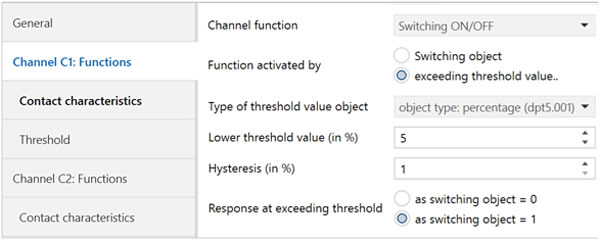

However, if you have a simpler system that only requires an on/off signal, you can still take advantage of this simple yet intelligent approach, as some actuators, such as those from Theben, allow a value to trigger the output.

By combining the two functions, you are able to have multiple devices all controlling one output without the need for any additional logic or devices.

Conclusion

This is a great example of the flexibility and high functionality that KNX offers. Although the requirements for the project may not fit within the ‘standard’ approach, there is always another way, be it with a device that has the intelligence to solve the problem or with a manufacturer that offers an innovative approach.

If you’re ever in a position where you can’t work out how to approach a problem or are getting unexpected results, then take advantage of the extensive range of KNX experts that are willing to help. It could be a KNX consultant, a KNX distributor, training centre or a manufacturer. Whichever you choose, there is always someone available to help!

Mark Warburton is the Technical Director of Ivory Egg (UK) Ltd, a supplier of leading KNX products and provider of KNX training courses.