By Simon Buddle, Future Ready Homes.

By Simon Buddle, Future Ready Homes.

It is a constant source of joy to me just how bad some people are at giving directions. ‘If you go up here about half a mile, you’ll see a turning on the left – it’s not that one. Go another half a mile or so and you’ll see a lay-by with a snack bar in it – mind you, it’ll be closed by now. Just after that there’s a big house on the right – go a mile past that and at the roundabout, take a left.’ Now I am sure that these directions are given with the very best of intentions. Yes, they may be helpful, but concise they are not. Like a long meandering country lane, they roll endlessly on, and kind of miss the point.

Most of my work really revolves around programming, but I do see quite a lot of paperwork of various denominations. There is, on all jobs, a lot of information that has to be passed around between all parties; installer, electrician, programmer – everyone needs to know how it all fits together so that they can do their little bit of the jigsaw. Inevitably the quality of the information varies hugely from job to job, and may well involve an electrical contractor who uses only a sharpie to write on cables, or some form of arcane wrapping of earth tape around each cable to identify it. I bet you’ve seen one of those.

There’s no point writing ‘data’ on a CAT6A cable. Nor does the name of a person work. The information has to be accurate and relevant.

Accuracy

Ultimately, cable X should be wired into connector Z if the lights are to come on when the button on the keypad is pressed, but how many of you have had at least one nightmare job where the electrician has wired the panel either, using out-of-date information, or they’ve decided to just land the cables where they want? However it has happened, it’s going to be a massive pain to rectify.

Creating wiring schedules, control schematics, floor plans, lighting schedules, panel connection documentation, building panels, and programming panels are all hugely time-consuming jobs, and anything that takes time, should be paid for. After all, that’s why we’re in business – to make some money. This means that anything we commit to paper has to be correct, because someone has paid for our time to create it. But more than that, it all has to be correct from end to end.

Ultimately there are only two details that matter:

1) Is the circuit connected to the correct module and output?

2) Is it programmed onto the correct button in the system?

Documentation

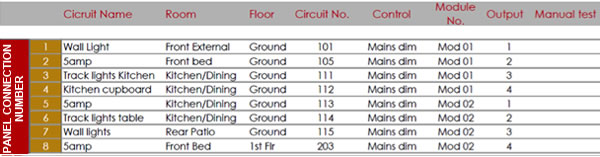

The first step in delivering these two elements is documentation. I have been working on a project with a company called Custom Sight and Sound recently, and I’m going to give them a shout out because their documentation was fantastic – they absolutely nailed it. The KNX panel wiring layouts had the same circuit references as the keypad button functionality schedules. This made programming very easy. I built the Group Address structure using the same circuit references. Every detail could be cross-referenced across multiple documents – no small feat.

Programming

For me, the programming requires two steps. Firstly, there has to be a panel handover from the electricians to the installer. I prefer to do a formal witness test using the manual buttons on the front of each module. This means that no programming is involved and therefore no ambiguity. This test simply answers the question ‘Does that output supply power to the correct circuit?’ If not, it will be down to the electricians to resolve. Once this step has been successfully signed off, you can move onto the keypad buttons. The onus is now on the programmer to prove the software connection to the right module output is correct.

Separating out and proving hardware controls followed by software provides easy visual clarity for both parties by creating clear lines of demarcation, responsibility and accountability. Good documentation goes a long way to facilitating these tests, but ultimately, it has to be witness-tested onsite before the project moves to the next stage.

Conclusion

Delivering a successful project is down to a collective team effort, probably across multiple businesses, all working towards the same common goal. There will be stress points as the project progresses, changes and money worries. Good documentation is a massive help. And just like with building sign off, witness testing and a formal handover are key. If you know that the people before you have done their bit right, it makes it all the easier for you to deliver your section of the project.

Simon Buddle CEng MIET, is a consultant for Future Ready Homes, a specialist in BMS and ELV services system design.