By Simon Buddle, SMC.

By Simon Buddle, SMC.

There is always a deep end at a swimming pool, well, nearly always. It’s clearly sign-posted and people who don’t wish to be in it stay away. I didn’t learn how to swim until I was eleven, and true to the stereotype, I was thrown in the deep end by my uncle. Sink or swim, there is clarity of choice. Survival will drag you kicking and spluttering to the surface and get you to the side. It will not, however, teach you how to swim. Indeed it is most likely to steer your subconscious mind away from the water.

As your business grows, I’m sure you’ve felt the danger of the deep end. Those little jobs that we started out with grow to larger projects, and suddenly, one day, we are faced with a Behemoth, with hundreds of devices, multiple headends and an almost incomprehensible timescale.

Just like swimming technique is taught in the shallows, so good panel design and building should be practiced and honed on our smaller jobs. Whether large or small, I do believe that the application of some simple rules and techniques will provide us with a successful, repeatable and importantly, profitable outcome.

Building Off-site

Ergonomics would dictate that it is far easier to build our panels offsite. We have the tools, materials, the work bench, and testing facilities all readily available. We have no distractions from other trades or other building-site-specific concerns such as power outages or, typically, a dirty environment.

Room for Expansion

There should also be a pragmatic approach to panel building. Ensure that you have more than enough space internally. Initial design scope should take into consideration possible future expansion, and of course, additions during the project, (Did somebody say ‘scope creep’?)

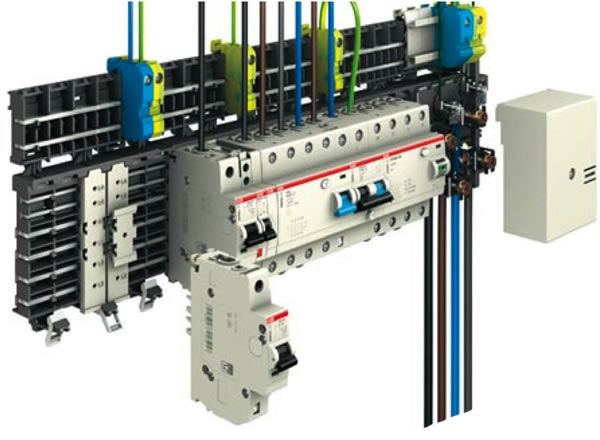

Make sure that there is space for connectors for external cables with a labelling scheme that matches your design documentation, add in containment and DIN rail, and you’re heading towards a great panel design. Some manufacturers, such as ABB, provide a busbar system that will enable the power and communications to run over the mounting rails, saving both time and money as no wiring is required between devices. It’s worth noting that these types of system are not interchangeable between manufacturers. In our KNX world, we are very accustomed to picking product from many different manufacturers, so it’s really worthwhile understanding all of the constituent parts needed before diving headlong into a busbar system.

Power

Safety is clearly of paramount importance, and this brings us neatly on to power. Mains power will be required by many devices. A rail of multiple live, neutral and earth connectors is my preferred method, but some like to loop in and out from one product to the next. Whatever your choice is, ensure the AC power is isolated or easy to isolate when the panel door is open.

If DC power supplies are required, always oversize them by about 25% – I’ve seen way too many 1A-rated products with 1A supplies fail out in the field. Do keep an eye on voltage drop though – it may be the neatest solution to install the DC supply in the panel, but with a long cable run, it is not always the best technical solution.

Hand/Off/Auto

Hand/Off/Auto – now that is a large switch! The HOA logic must be programmed so that when the HOA is set to Off, the equipment will not run regardless of freeze protection or other logic, and it will not generate alarms. However, when the HOA switch is set to the On position, the equipment will shut down due to any software or hardware safety that would normally shut down the equipment. In other words, it has to provide the function for which it has been designed, and that requires a conversation with whoever is writing the software.

Design Documentation

Design documentation ought to be standard practice, and with a little forethought and planning. there’s no reason why our panel shouldn’t be totally designed in software. This will undoubtedly take up a bit of your time initially, but crucially, it will save a huge amount of time during the build process. At the other end of the project, once installed and finished, we should keep a record of changes and issue a set of as-built drawings/documents. Why? Because we’ll need them when we go back to service the job.

Conclusion

Of course large panels can be and often are farmed out to specialist firms to build. There is nothing wrong in enlisting the services of a professional panel builder to create the panel you’ve designed, and indeed I’d encourage you all to get to know a company that can provide you with such a service. It is, however, true to say that doing it in-house will retain more of the project profit for your company, and raise your skills and knowledge, enabling you to deliver the complete solution. Following these few simple guidelines should help you to create technically-robust solutions that you can build time and time again.

Simon Buddle is the Technical Director of SMC – systems integration consultants and installers. Simon is also a regular contributor to KNXtoday.