By Simon Buddle, Future Ready Homes.

By Simon Buddle, Future Ready Homes.

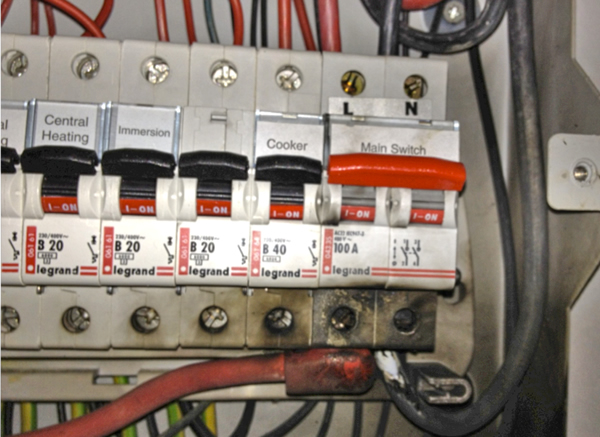

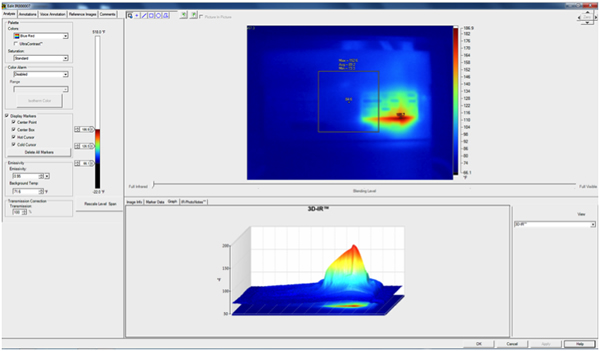

It is pretty dull when you get called out over the weekend and travel to site only to find out that a breaker has tripped in the electrical consumer unit. But it is not nearly as dull as when it hasn’t tripped and something in the panel has been fried or much worse. Incoming power control and protection is often left to others by installers. This tactic works well in terms of demarcating our low-voltage world from the on-site electricians, but it doesn’t work quite so well for the purposes of maintenance, nor ultimately, customer happiness.

Regulations and Standards

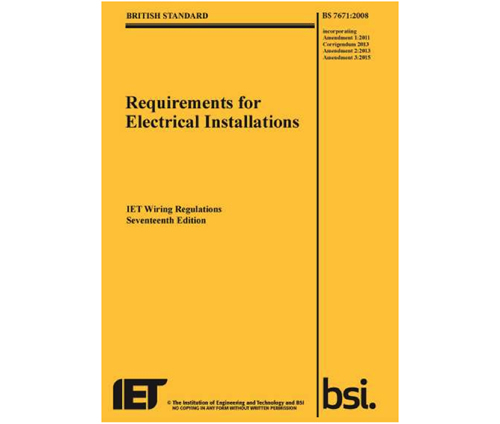

In the UK, the British Standard BS7671 is undergoing its third cover change in four years. The third amendment to the 17th Edition is due out next year, and once again, the onus is being placed on greater safety. Overhead cable ways must use metal clips to hold them in order to prevent plastic trunking or conduit from melting and leaving cables hanging loose. Tragically, this change was brought about as a result of the death of two courageous firemen in Stevenage in 2005.

Further changes are likely to be brought in governing the use of RCDs (Residual Current Devices). British Standard BS 7671:2008 defines supply system low voltage as:

50-1000V AC or 120-1500V ripple-free DC between conductors.

50-600V AC or 120-900V ripple-free DC between conductors and Earth.

We, as the designers and installers of low-voltage cabling and low-voltage panels/enclosures (covered by BS EN 61439) have a responsibility to ensure that our systems are safe and fit for purpose. Are there holes in your panels over the DIN rail where hands could get in and touch cables? Does the panel require a special tool to access it? Once the panel cover clips have broken, it is no longer deemed safe.

Breakers

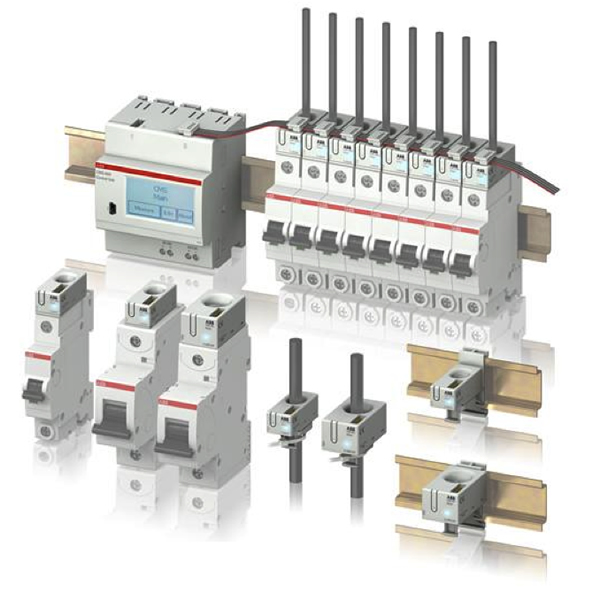

Nuisance tripping of breakers has been a topic within the regulations for a while, and it is worth a thought from the client’s perspective. If something trips, what will stop working in the home? For example, a single master RCD in the panel will cause all KNX components to stop working. This is not great when you have spent a lot of money on an integrated and intelligent solution. Nuisance tripping may be due to residual current build up, but the breaker may be tripping due to overload, short circuit or earth leakage. If the installation is correctly designed however, all of these problems can be avoided.

An RCBO (Residual-current Circuit Breaker with Overload protection) is simply a combined MCB (non-residual-current circuit protection device or Miniature Circuit Breaker) and RCD, and we are required to put one or other on lighting circuits, bathroom circuits, and socket outlets amongst others. It is, in my view, always good practice to install a ‘master isolator’ switch into the panel. However, with all circuits effectively requiring RCBO/RCD protection, this device should not be an RCD. If it is, you run the risk of nuisance tripping the entire panel as the electrical fault conditions will define which one goes first.

Design and Planning

Ultimately, we are responsible for the panels that we install since we are the ones who sell them to the purchaser. In the UK, everything we design must comply with BS7671 and BS EN61439. A considered approach to the breakers will require some basic calculations to ascertain the total current in (main isolator switch size + overhead), and it will also enable you to correctly size the internal cabling for the panel.

The cable current capacity should always be higher than the breaker so as not to create a risk of overheating and fire inside the panel. There are many conversations and calculations to detail this exactly, but this simple rule of thumb will always keep you on the safe side of calculation. Therefore a 6A breaker will have a 10A cable, and a 10A breaker a 16A cable, and so on. BS7671 provides very detailed tables and charts to correctly work out this discrimination.

Panel product layout may well be a factor too, ensure that there is at least 25% spare space and load capacity. It may be worth considering dedicating a panel to each floor of a building, and within the panel, assigning the breakers in such a way that they are consistent from floor to floor.

A consistent design approach will bear fruit both in panel build efficiency and later on when maintaining the system or doing simple fault finding over the phone with the homeowner. Should you charge for your design time? Of course! You are providing a professional service. As the designers of lighting systems, your name should be recorded on the test sheets.

Designing electrical systems correctly is the single most important part of any installation. That includes the selection and erection of the electrical system to be in line with regulations (Guidance Notes 1 and BS7671 in the UK).

Conclusion

Everyone should be safety conscious; as KNX contractors, we have an obligation to design, install and maintain systems that are safe. Every new job gives us the opportunity to re-evaluate our processes, documentation, methods of working and safety record. By constantly reviewing and critiquing our work, we are demonstrating a clear desire to maintain or improve the standards within our own company, which can only be a good thing for the business and the customer.

Further Reading – Excerpts from BS7671:2008 A2

• All socket-outlet circuits must have additional protection, for a domestic job this means a 30mA RCD. And this means all socket-outlets, not just those used for outdoor portable equipment. This regulation applies to socket-outlets of less than 20A and which are used by an ‘ordinary person’ – a person who is not skilled, i.e. who has enough technical knowledge or experience to avoid danger that electricity may create; and who is not instructed, i.e. sufficiently advised or supervised by skilled persons so that they may avoid any danger that electricity may create.

• Socket-outlets do not need an RCD if they are under supervision of skilled or instructed persons, for example in a commercial or industrial location.

• Socket-outlets used and specifically labelled or identified for use with a particular piece of equipment do not need RCDs, for example with a domestic appliance such a freezer, which may be prone to frequent RCD tripping.

• Cables hidden in walls or partitions less than 500mm beneath their surface must be impact protected. This can be achieved by: using a cable complying with regulations relating to impact protection; by running the cable in earthed sheath conduit, or trunking or ducting; or by providing mechanical protection against penetration, for example by nails. Cables which are not mechanically protected, or are not installed under the supervision of a skilled or instructed person, must be RCD protected and run in “safe zones” – horizontally or vertically to the outlet point.

• Cables installed, at any depth, without mechanical protection in a partition which is internally constructed of metallic parts must be 30mA RCD protected.

• Lighting circuits must be RCD protected, but nuisance tripping of multiple lights can be avoided by running lighting circuits on separate RCDs.

Simon Buddle is a consultant for Future Ready Homes, a specialist in BMS and ELV services system design. Simon is also a regular contributor to KNXtoday magazine.

You are welcome to comment on this article. See below.